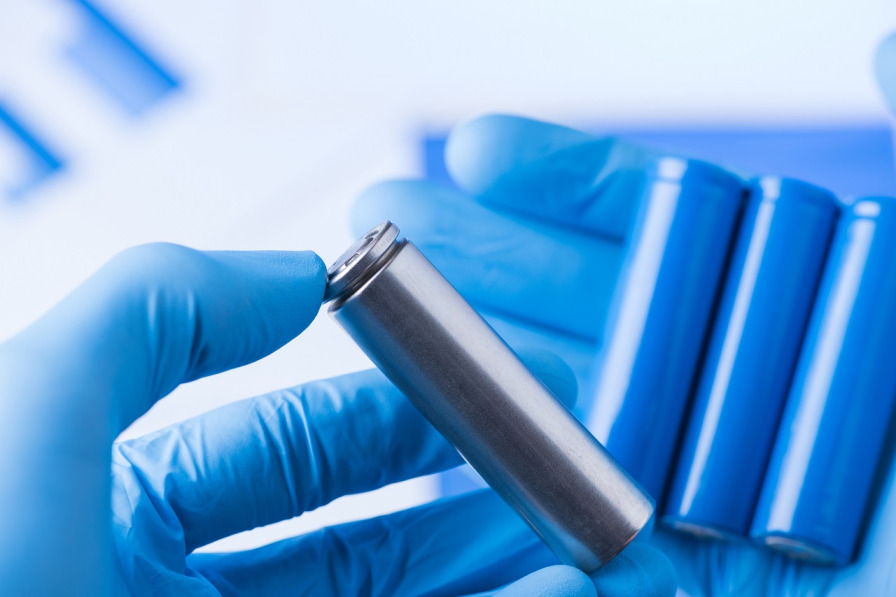

Scientists in California Develop a New Recycling Process for Lithium Batteries

- By Adam Watts

- 9 Feb 2018

Scientists in California Develop a New Recycling Process for Lithium Batteries

Scientists at the University of California have developed a new recycling process that restores old Lithium battery cathodes to excellent condition using half of the energy that the current restoration processes use.

Current methods involve breaking down the cathodes into separate elements that have to be put together again, whereas the new process produces compounds that are ready for use in a new battery.

The new method works on the lithium cobalt oxide batteries which are used in laptops and smartphone and also on the larger and more complex lithium-nickel-manganese-cobalt batteries which are found in electric cars.

The problem of batteries in landfill

Less than 5% of lithium batteries are recycled today and this means that millions of batteries are being sent to landfill where they leach toxic waste into the soil and waterways. Not only this, the batteries contain precious materials like cobalt and lithium, and the supply of these natural resources is dwindling fast. We need to recycle far more batteries than we are recycling currently if we are going to keep up with the ever-increasing demand.

How batteries are usually dismantled

Many companies already dismantle batteries, and most of these are in China. The batteries are usually crushed, then they are melted or dissolved in acid. This separates the metals like cobalt, lithium, nickel, and manganese. The process uses large amounts of energy and destroys the value of the battery cathodes.

The new process

The new method that the scientists have developed preserves the structure of the battery cathode. They remove the cathode material and soak it in a hot lithium salt bath. They then dry the solution, which produces a powder that is heated to 800 degrees then cooled slowly. The new process uses half of the energy of the standard process and allows the scientists to make new battery cells with the regenerated cathode material. The new cathodes have the same storage capacity and battery life as the old ones.

The race to develop new processes

Two other companies, based in San Francisco and Oregon, are trying to develop the new process further to allow them to apply it on a larger scale. The consensus is that the more companies who are investing in these technologies the better, given that lithium batteries are evolving so quickly, and recycling them is so valuable.

Challenges and opportunities

A challenge that the scientists face is finding more efficient ways to separate the cathode material from the body of the battery and make it viable on a large scale. The Californian scientists are working on the process further so that it can be used on any lithium battery, and they are currently talking to a Chinese battery processing company that is considering trying the new recycling method.